Optimizing Steel Framing Workflows with Scottsdale’s Roll Forming Technology

In today’s fast-paced construction landscape, light-gauge steel framing is transforming how buildings are designed and built. With its precision, strength-to-weight advantages, and ease of prefabrication, light-gauge steel framing is fast becoming the go-to solution for developers and contractors worldwide. To unlock the full potential of light-gauge steel construction, pairing it with an efficient design process enhances results, especially when using advanced roll forming technology from Scottsdale Construction Systems.

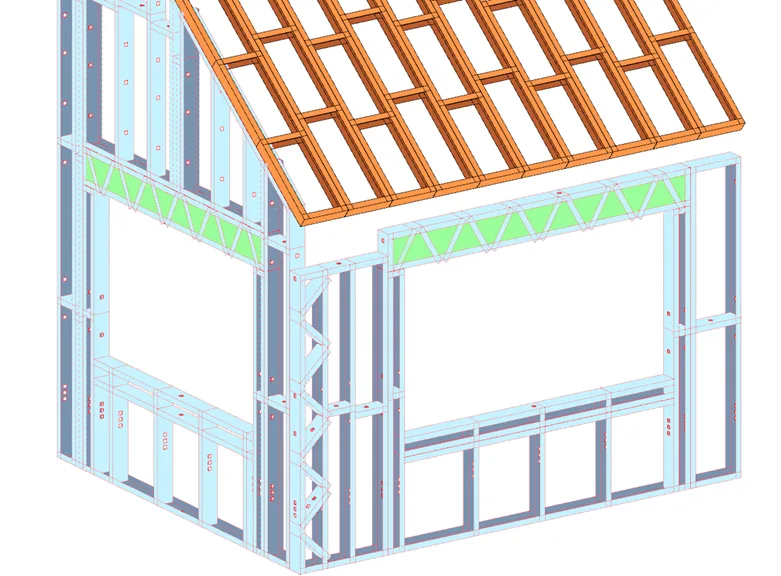

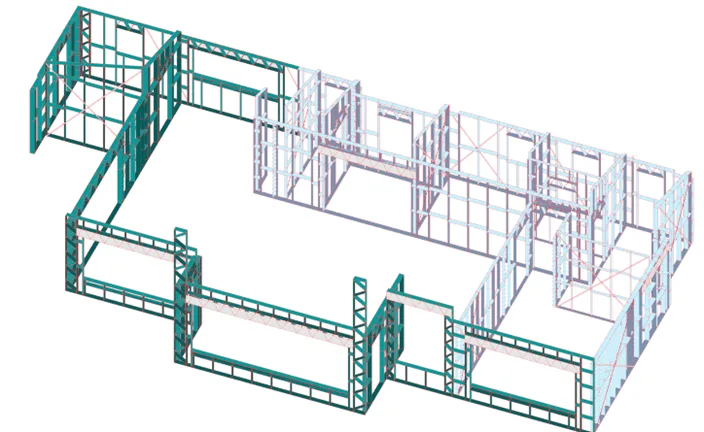

This article walks through the essential stages of a steel framing design timeline, specifically for projects using light-gauge steel members, including wall panels, trusses, and complete framing systems. Whether you’re detailing walls, floors, or roofs, understanding this workflow ensures a smoother path from concept to production.

Understanding Light-Gauge Steel Framing Project Requirements

Every successful light-gauge steel framing project begins with a thorough understanding of the architectural and engineering inputs. While project files in many regions are delivered in CAD or PDF formats, they often lack critical information such as connection details or comprehensive structural load data.

In the initial kickoff meeting, detailers assess the wall layouts to determine how they need to be adapted for steel framing. This step is crucial, especially when the original design was not intended for light-gauge steel, considering how wall finishes affect panel placement. They also evaluate potential plumbing clashes between floor levels and the steel framing structure, which could impact framing routes. Changes in floor elevation are carefully reviewed, as they can influence lintel heights and stair step configuration.

Attention is given to the tolerances for door and window openings, where inaccurate dimensions may lead to costly resizing. Tolerances for jambs, sills, and headers must be precise. Finally, the availability of load data is verified early, as this is essential for designing and positioning light-gauge steel trusses with accuracy and efficiency. Without accurate load data, truss placement becomes impossible, and changing loads mid-project can be disastrous.

Initial Steel Framing Design Phase

With the groundwork complete, the design process for the light-gauge steel framing project moves into its initial design phase. At this stage, it’s important to maintain entire wall sections intact within the model. It is recommended to avoid cutting walls early. Keeping walls whole allows for faster property editing in the initial design phase, allowing for faster and more flexible adjustments as the project evolves.

As challenges emerge, they should be flagged and documented for resolution in upcoming review sessions. This proactive approach ensures that no critical issue is overlooked. The early design phase also serves as the preparation point for more detailed modeling work, forming a strong foundation for the precise development of light-gauge steel studs, light-gauge steel trusses, and steel framing panels to follow.

Collaborative Coordination in Light-Gauge Steel Framing Design

The design process for any project is rarely a straight path. Every project requires ongoing collaboration among detailers, engineers, and architects to keep the project aligned with both structural and architectural goals. These iterative meetings play a critical role in identifying and resolving any design clashes that may arise, while also accommodating last-minute changes to the architectural plans. During this phase, the team works together to confirm that all structural alignments are accurate and that bracing strategies for light-gauge steel members are properly integrated into the overall steel framing system.

Detailing for Performance: Finalizing Steel Framing Members and Steel Trusses

Once the framework for the light-gauge steel framing project is done, the final detailing phase can begin. At this stage, detailers focus on manually refining elements such as beam pockets and custom openings to ensure a precise fit within the structure. Structural components like lateral resisting systems, X and K bracing, are integrated to enhance overall integrity and meet engineering requirements.

The steel framing panels are then strategically segmented for ease of transportation, ensuring they arrive at the job site ready for fast and efficient assembly. Every aspect of the detailing process is finalized to meet both the structural demands and the aesthetic expectations of the project, ensuring that all light-gauge steel members, including walls and trusses, perform as intended within the completed system.

Collision Testing and Final Checks Before Roll Forming Steel Members

Before exporting the light-gauge steel framing model to the roll former, it is essential to verify that every component fits together seamlessly. This begins with running a comprehensive collision test to detect any potential design conflicts that could disrupt assembly. Scottsdale’s advanced simulation tools are then used to preview each panel, allowing for precise review and approval.

Professional Design Tip

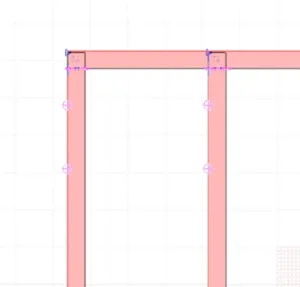

Use color-coding to streamline your workflow. As panels and elements are approved, update their color to green. This simple visual cue provides an efficient way to track progress, avoid confusion, and manage approvals throughout the design process.

Additional final steps include adding all necessary service holes to the light-gauge steel framing members and renaming each panel with consistent, logical conventions. With all checks completed and the final steel framing model approved, the project is ready to be exported to ScotRF software and sent to Scottsdale’s roll forming machines for fabrication, ensuring smooth, accurate production of every light-gauge steel component.

Mastering Steel Framing Design and Roll Forming with Scottsdale’s Technology

Success lies in mastering the design workflow. Scottsdale’s technology empowers teams to streamline every phase of the steel framing design timeline by reducing errors, saving time, and delivering higher-quality results with every steel framing project. By following these best practices, detailers and designers can confidently navigate light-gauge steel framing design, from concept to roll formed reality.

Scottsdale Construction Systems can help in the design process as well as roll forming and fabrication process of light-gauge steel construction. Learn more about our roll forming technology, our state-of-the-art software and our complete roll forming ecosystem by contacting us at sales@scottsdalesteelframes.com or call us at +1 (888) 406-2080.