Modern construction now relies on cold-formed steel, advanced roll forming machines, efficient steel framing, automated steel fabrication, and fully engineered cold-formed steel framing systems. Scottsdale aligns all these components into one unified design-to-production ecosystem built for accuracy, consistency, and speed.

Integrated Design and Software for Cold-Formed Steel

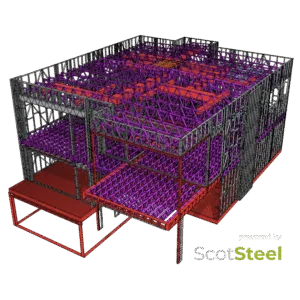

Scottsdale focuses on integrated software and design for material efficiency. Our focus is to offer our customers roll forming machines that can produce ready-to-assemble CFS panels and CFS trusses. This foundation ensures steel framing workflows that are predictable and repeatable, providing meaningful value for customers scaling CFS fabrication. By enhancing automation across every stage of steel fabrication, Scottsdale strengthens the performance of modern steel framing machines and the reliability of cold-formed steel framing on every project.

Our system is built to create a faster, more direct workflow from design to assembly. Our strength lies in our software’s ability to optimize designs, reduce waste, and facilitate complex designs. These capabilities highlight how cold-formed steel engineering, paired with automated roll forming machines, advances the industry’s shift toward smarter steel framing and more adaptable CFS fabrication solutions.

High-Output Roll Forming Machines for Reliable Steel Fabrication

Scottsdale offers roll forming machines with high-volume output and commercial-grade systems. We offer a wide variety of roll forming systems for CFS wall panels, CFS floors, and CFS trusses. These systems bring speed and accuracy to steel fabrication, increasing consistency while reducing manual effort. For customers scaling production, our advanced steel framing machines provide durable capacity for heavy cold-formed steel framing applications.

Our roll forming machines can fabricate heavy steel gauges for stronger frames. Our systems use heavy-grade coils, fabricate frames with flat flanges with our lip-cutting tooling, which leads to easier installation. Scottsdale offers additional tooling kits to swag, cut, notch, punch, and modify cold-formed steel members as designed. These features significantly improve steel framing performance and simplify critical stages of CFS fabrication, especially for builders working with demanding steel fabrication requirements in large-scale environments.

End-to-End CFS Fabrication and Steel Framing Support

Scottsdale offers an end-to-end system, including design software, production management tools, training, support, data-driven production, in addition to business operation tools, and support for our customers. These resources elevate the capabilities of cold-formed steel, streamline the operation of roll forming machines, and improve the consistency of steel framing across all project types.

Our roll forming machines offer steel framing solutions with a focus on speed, precision, and efficiency. We offer versatile roll forming machines and software for streamlined building processes. These strengths reinforce the reliability of Scottsdale’s approach to CFS fabrication, expanding the possibilities for automated steel fabrication and advancing the performance of global steel framing machines within modern cold-formed steel framing methods.

Single-Profile and Multi-Profile Options for Every Business Model

We offer single-profile roll forming machines for those customers seeking high efficiency. We also offer multi-profile roll forming machines for those customers seeking versatility in CFS fabrication and building larger, more complex CFS framed buildings. This flexibility supports a variety of steel framing business models and strengthens the scalability of steel fabrication strategies for companies building with steel framing machines.

We are well known for our integrated design, engineering, structural analysis, and machine controls, all in a single seamless software workflow. Our software includes ScotSteel, ScotStruct, ScotRF, and we are integrated with over 20 third-party engineering and manufacturing software solutions. These advanced tools enhance cold-formed steel engineering, guide precise roll forming machines, and enable streamlined steel framing and CFS fabrication from start to finish, ensuring strict compliance across all cold-formed steel framing applications.

Certified Cold-Formed Steel Framing for Global Markets

Cold-formed steel profiles fabricated by our roll forming machines are certified through third-party ICC certification to ensure all profiles comply with building codes. Our ICC reports cover the US market, NZ, AU, Saudi Arabia, and beyond. This certification reinforces the accuracy of steel fabrication, the reliability of steel framing, and the performance of Scottsdale’s steel framing machines within the global cold-formed steel framing standards.

Scottsdale roll forming machines are high-speed, automated equipment that minimizes manual labor in steel fabrication and steel framing and maximizes output. We give our customers the option to fabricate their steel framing panels with rivets or screws. We serve the global market, and it is important for us to offer our customers the exact solutions that would serve their markets and their business.

Scottsdale Leads in Steel Framing and Roll Forming Machines

Scottsdale provides roll forming systems for different business models, specifically differentiating between highly efficient dedicated profile systems and more versatile multi-profile systems for varying project types. We are a leader and innovator in steel framing machines, industry pioneers, and a leading global supplier of roll forming machines. We offer sophisticated, integrated systems that enable efficient design and fabrication of cold-formed steel framing for a wide range of construction projects.

The choice to go with Scottsdale roll forming solutions is easy. We have many equipment options to fit a wide range of project requirements, preferred assembly methods, and flexible workflow and options. Scottsdale is the preferred choice when it comes to steel framing machines and advanced roll forming solutions.

Scottsdale Knowledge Base is a comprehensive repository of information, data, design aids, tools, expert advices, manuals, and many other resources on prefabricated steel framing.

Not only is it a powerful tool for any architect, engineer, contractor, framing shop, homebuilder, building material supplier, or anyone involved in cold-formed steel framing, it also enables seamless integration of Scottsdale’s industry-leading steel framing roll former equipment and technology into virtually any work flow. All licensed customers and ScotSteel subscribers receive complementary access to Knowledge Base. Become a member today of our ScotAI-assisted steel-framing information platform, and elevate your business!

Additional Scottsdale Roll Forming Solutions and Resources

- Blog – How to Compare Roll Forming Machines and Clarify Misconceptions

- Blog – Understanding the Energy Consumption of Roll Forming Machines

- Blog – Overcome Complex CFS Truss Design with New Steel Framing Technology

- Blog – How to Make Walls and Ceilings with Roll Forming Technology

- Blog – Better Results for 3D Printing Homes with Roll Forming Technology

- Video – The Best Containerized Factory Solutions for Remarkable Steel Homes

- Financial Services

To learn more about Scottsdale’s roll forming solutions and steel framing ecosystem, visit us at www.scottsdalesteelframes.com, call us at +1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info.